Color Choices and Powder Coating

S.T.A.R. railing systems are coated with a durable esthetically pleasing finish process called powder coating. S.T.A.R. railings offer a choice of powder coated color offerings displayed below.

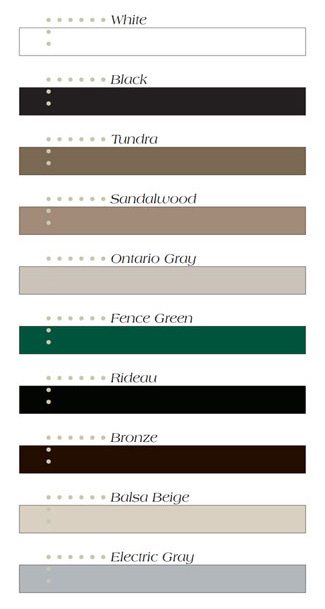

Standard Colors

- Black

- White

- Textured Black

- Oil Rub Bronze

Available Colors

- Sandalwood

- Ontario Grey

- Bronze

- Electric Grey

- Anodized Aluminum

- Rideau

- Fence Green

- Tundra

- Balsa Beige

- Almond

Please Note: All colors shown may not be available in your geographic region – consult with your local S.T.A.R. dealer for additional information and availability. Colors displayed are reproduction only and may not accurately represent true color. Refer to actual color samples for true color representation.

Custom colors are available. Optional custom color selections are available in a infinite choice of colors and finishes to meet your project needs. We can provide either a infinity number of “off the shelf “alternatives or we can custom blend any color to meet you project needs and desires.

Standard coating offering meet AAMA 2604 voluntary specification performance requirements and test procedures for high performance organic coating on aluminum extrusions and panels and optional coating to meet AAMA 2605 compliance are available.

All product are covered by S.T.A.R. warranty protection plans.

What is Powder Coating?

Powder coating is a type of coating applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form.

The coating is typically applied electrostatically and then cured under heat to allow it to flow and form a “skin”. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. Powder coating is mainly used for coating of metals, such as aluminum extrusions in architectural building materials (guard rails), automobiles and bicycle parts.

Some advantages of powder coated finishes over liquid coating include:

- Powder coatings emit zero or near zero volatile organic compounds (VOC).

- Powder coatings can produce much thicker coatings than conventional liquid coatings without running or sagging.

- Powder coating over-spray can be recycled and thus it is possible to achieve nearly 100% use of the coating.

- Powder coating production lines produces less hazardous waste than conventional liquid coatings.

- Powder coated items generally have fewer appearance differences between horizontally coated surfaces and vertically coated surfaces than liquid coated items.

- A wide range of specialty effects is easily accomplished which would be impossible to achieve with other coating processes.